Marker Dropper Prototype

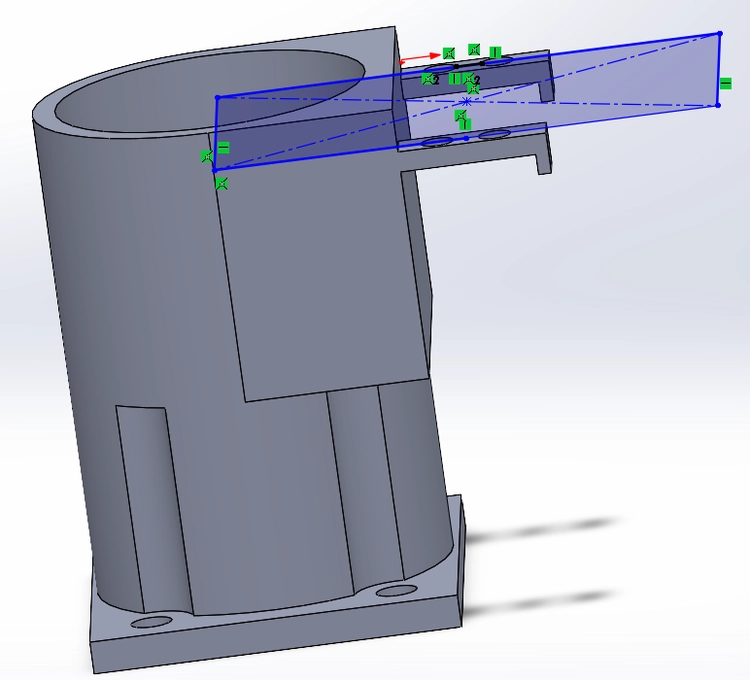

Below is a prior version of MuddSub’s dropper subsystem, which the Mechanical team redesigned in my sophomore year to dispense two dodecahedron markers at staggered times from shorter, parallel tubes. A single servo with two panels of different sizes rotates these panels, separately uncovering the markers so that they can be dropped into designated containers during the RoboSub competition.

Each marker, designed by my friend and previous Mechanical team lead Jordan, is built from two halves, packed with miscellaneous hardware and assembled with a screw and nut. The high mass within and flat faces around the volume of the markers is meant to ensure they descend quickly and stay in place after being deployed underwater, which preliminary testing has verified works extremely well.

After we make more progress with finishing touches on assembly for Alfie and return to fabrication of Crush, the AUVs that this and other subsystems will mount onto, we’ll return to working on this dropper prototype, modifying the design to be more compact and actuated by a continuously-controlled servo, instead of a discretely-controlled servo, for higher timing precision.