AUV Fabrication

In my freshman fall semester, I entered the machine shop for the first time as I learned how to use the mill to drill and tap holes for the thrusters on MuddSub’s first AUV, Alfie. I also assisted with disassembly and reassembly of Alfie’s bellypan, the baseplate on which the thrusters, electronics hub, and mechanical subsystems are mounted. While these were ultimately small steps, I’m proud to have contributed to a fully-operable custom AUV! Here’s a quick video of MuddSub’s president Ket driving Alfie around in Mudd’s tank room.

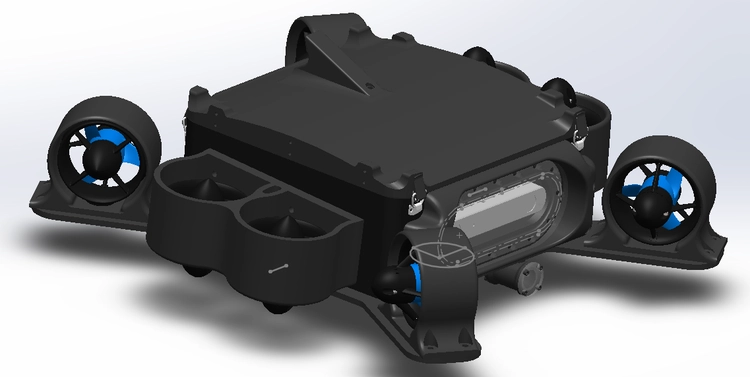

While the video demonstrates that Alfie does its job, the RoboSub competition allows teams to deploy two AUVs simultaneously. Crush is MuddSub’s completely reimagined take on Alfie. Although the majority of the robot was previously designed, I’ve been able to contribute some input to finishing touches, especially now that we’ve moved into fabricating components. This includes Crush’s bellypan, whose geometry I was tasked with realigning with respect to other parts, such as 3D-printed carbon fiber thruster housings, an acrylic camera enclosure, and a lid that was previously milled at a CNC shop. The Mechanical team is preparing to find where to get this and many other components waterjetted and welded professionally, since watertightness is of the utmost importance.