Gladius II Research & Fabrication

During my freshman and sophomore years, as we were designing and assembling Gladius II in preparation for the launch, I assisted the Structures team in finding materials for structural components and actually fabricating those components, before building the rocket with them. Along with staying wihtin our budget, one guiding principle from the beginning was minimizing mass. Gladius II was designed around a Cesaroni O3400 motor, which would need every mass reduction it could get to achieve our ambitious altitude goal of 20,000 ft, from which we have since downscaled. I compared stress-strain curves and research abstracts for different aluminum alloys and composites, and brainstormed design alternatives for hollowing out parts to reduce mass (which we ultimately didn’t, as the savings were negligible). This helped my team settle on structural FRP for the centering rings and bulkheads, and identify ways to move forward for attaching components securely.

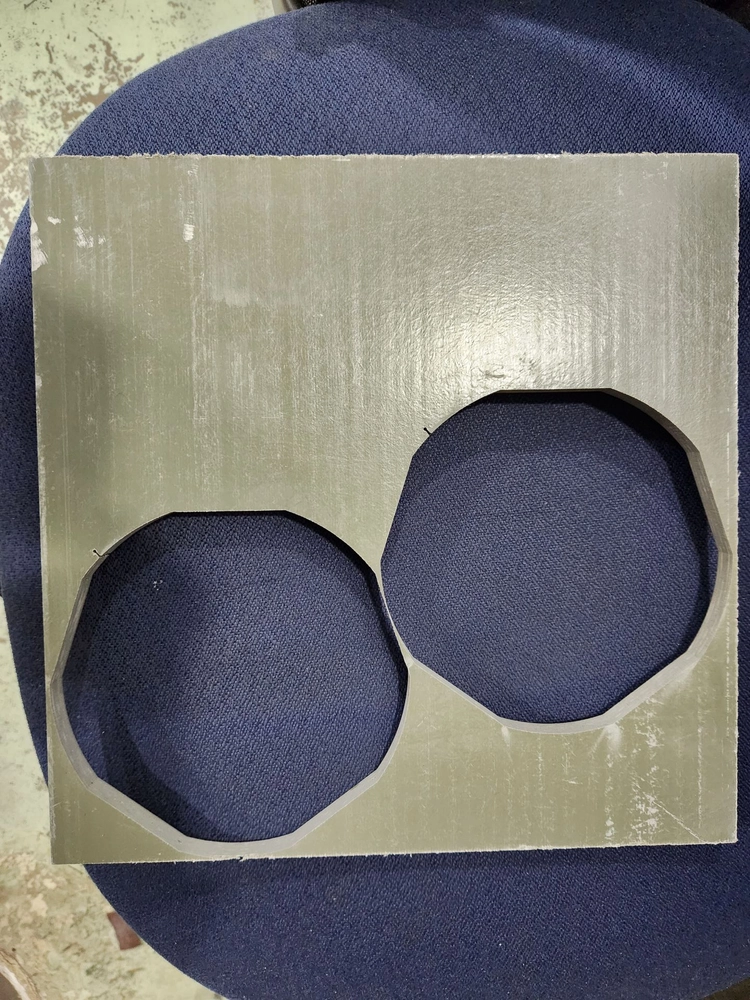

Beyond design input in efforts to minimize the mass of these structural components, I was most active in their fabrication, such as waterjetting bulkheads and centering rings, and trimming down fins via dremel, before helping my team epoxy everything to our airframe. Much of that experience will come in handy this year as we move from design to fabrication of Gladius III. To this day I’m still pretty proud of how tightly I managed to align our “pentagonalized centering rings” on the waterjet bed. These were designed by Structures veteran Anthony so that we could place them on their flat side on the mill bed and precisely drill out a screw hole on the opposing rounded side, achieving a flush fit with the airframe.