Design & Manufacturing

E4 “Remediation Station” Team Project

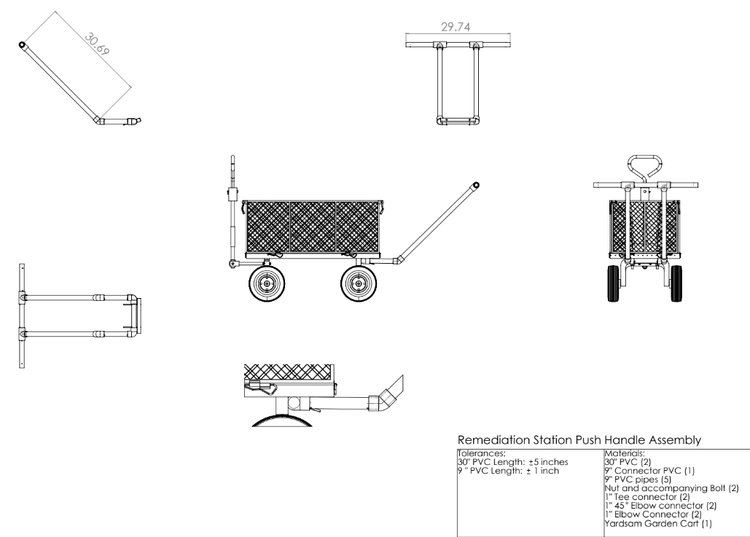

E4 culminates in a team project where students produce a solution to an external client’s engineering challenge. My teammates Sam, Bella, Cristina, and Adi and I were assigned to an awesome Mudd alum’s project proposal: find a method of transporting scraps and other waste from a mining claim over rough, steep terrain in Utah. With only $200 at our disposal, after much deliberation we settled on integrating a robust PVC handle system onto a heavy-duty garden cart, which our client has since had success using. It allows him and a friend (as opposed to just one or the other) to push/pull on the cart simultaneously, carrying upwards of 180 lbs of miscellaneous industrial waste 0.75 miles to and from a car.

This was a great exercise in professional engineering practice. Like every member of my team, I had opportunities to lead meetings with our client and our engineering advisor, and contributed not only to the actual work of identifying objectives/functions/constraints and conducting research, design, and assembly, but also project planning and documentation such as creating a bill of materials (BOM), process router, and even our own deadlines. One of the most significant challenges was down-selecting our ideas to land on something feasible for our budget and time constraints, which is of course foundational to any engineering design process. Here are some ideas we moved away from:

.webp)

.webp)

.webp)

E4 Machinist’s Hammer

In addition to the team project, E4 has students learn manufacturing techniques and basic geometric dimensioning and tolerancing (GD&T) by crafting their iconic machinist’s hammers, utilizing various equipment available on campus. E4 certainly grew my love for hands-on fabrication, and familiarized me with many of the tools I now use in the engineering clubs that I lead.

Students begin working up to the hammer by familiarizing themselves with the Machine Shop and Makerspace as they create their hammer stands and PVC ocarinas. Through these fun projects, I picked up a variety of tools like the lasercutter, mill, and lathe, and learned how to track my tolerances along the way. After some unfortunate mistakes where I had to restart parts of my hammer, I also significantly improved my time management and project planning. Most importantly of all, I learned about the importance of safe practice around powerful machinery, which has served me well as a shop proctor and mentor to future E4 students.